Delano Peak

All Mountains, Any Adventure.

The perfect balance between climbing and descending. All mountains, all trails, all day, every day. With the Delano Peak, every trail is the best trail.

Travel for Most Travels

Not too much, not too little. 150mm front and 135mm rear travel are perfect for just about any trail. It’s the Swiss Army Knife of bikes.

135mm rear

150mm Front

Nimble

Long enough to be stable, but balanced enough to be maneuverable. With a perfect blend of geometry and kinematics, the Delano Peak is responsive, playful, and efficient.

Frame Design

We lowered the shock placement and standover height by 2 in. This makes the bike more comfortable, increases stiffness, and allows for reduced weight.

Delano Peak Official Launch Video

Adventure's Bicycle

Designed from the ground up to excel on any terrain, the Delano Peak drives you to be creative and turn any line into the fun line.

REVIEWS

As you go to purchase your next bike, I encourage you to give Fezzari a look.

As you go to purchase your next bike, I encourage you to give Fezzari a look.

As you go to purchase your next bike, I encourage you to give Fezzari a look.

As you go to purchase your next bike, I encourage you to give Fezzari a look from a customer.

As you go to purchase your next bike, I encourage you to give Fezzari a look from a customer.

As you go to purchase your next bike, I encourage you to give Fezzari a look from a customer.

As you go to purchase your next bike, I encourage you to give Fezzari a look from a customer.

Full carbon, state-of-the-art, and beautifully crafted. The Delano Peak is ready for any mountain or adventure.

Build YoursRoom to maneuver

With a 73mm threaded bottom bracket, readily-available bearing sizes, and a frame designed to fit longer droppers, maintenance and customization are a breeze.

Responsive

The lively suspension platform will pop you off rocks, and progressively soak up bumps on landing.

Cleancast™ Carbon

Our unique carbon layup process cuts waste by 30% while still increasing strength and reducing weight, making our bikes both lighter and more environmentally-friendly.

The Delano has a perfect combination of trail and all-mountain geo. You'll feel balanced and comfortable in large variety of trails and mountains.

Tetralink™ Suspension

Progressive Tetralink™ design allows supportive mid-stroke for pedaling efficiently but acts like a pillow when hitting something bigger.

Built For Life

Our carbon frames have been tested at 130% of industry standards meaning the Delano will take you farther.

130%

Of Industry Standard

"Going downhill, it absolutely delivers, with an almost perfect blend of stability and playfulness. One tester even had his best-in-test downhill run on it."

"We put the Fezzari Delano Peak high on our recommended bike list. It is an easy call as it checks off so many boxes: lifetime warranty, customizability, great value build options, and most importantly, it is a ton of fun to ride."

"Our look at the details suggest that the company has done their homework."

"Initially (the factory direct) process may sound a bit cold and corporate, but in reality, it's quite the opposite."

"Fezzari is a company that has customer service on the brain."

"Fezzari also offers one of the best warranties in the business, a 30-day money back guarantee, as well as a 23-point custom bike fit to make sure they get the right bike size for you."

"Fezzari’s out-of-the-box thinking allows riders to afford bikes they would otherwise have to mortgage their house for."

Materials

Fezzari uses the highest quality materials available and the newest technologies to make sure that the bikes they make are the best you have ever ridden, guaranteed.

Less waste and lighter frames though better technology.

In traditional carbon layup processes, sheets of carbon are wrapped around an air bladder that has some type of object inside the bladder to keep the form, think of a paper mache project. Then after all the carbon is wrapped around the bladder, the object holding the shape is removed and the bladder and carbon fiber are placed in a mold. The bladder is inflated and baked. The problem in this process is that there is a lot of waste. The carbon wrapping has to be loose enough to pull the object out of the bladder before the curing process. This loose wrapping can cause overlapping carbon fiber that can weaken the frame or cause unnecessary weight, and creates air pocket voids causing potential frame failure.

Stiffness and strength.

We use carbon fiber on frames, seat posts, forks, and other components. Carbon fiber is very light and can be made stiff or flexible. The term commonly used to describe stiffness is ''modulus''.

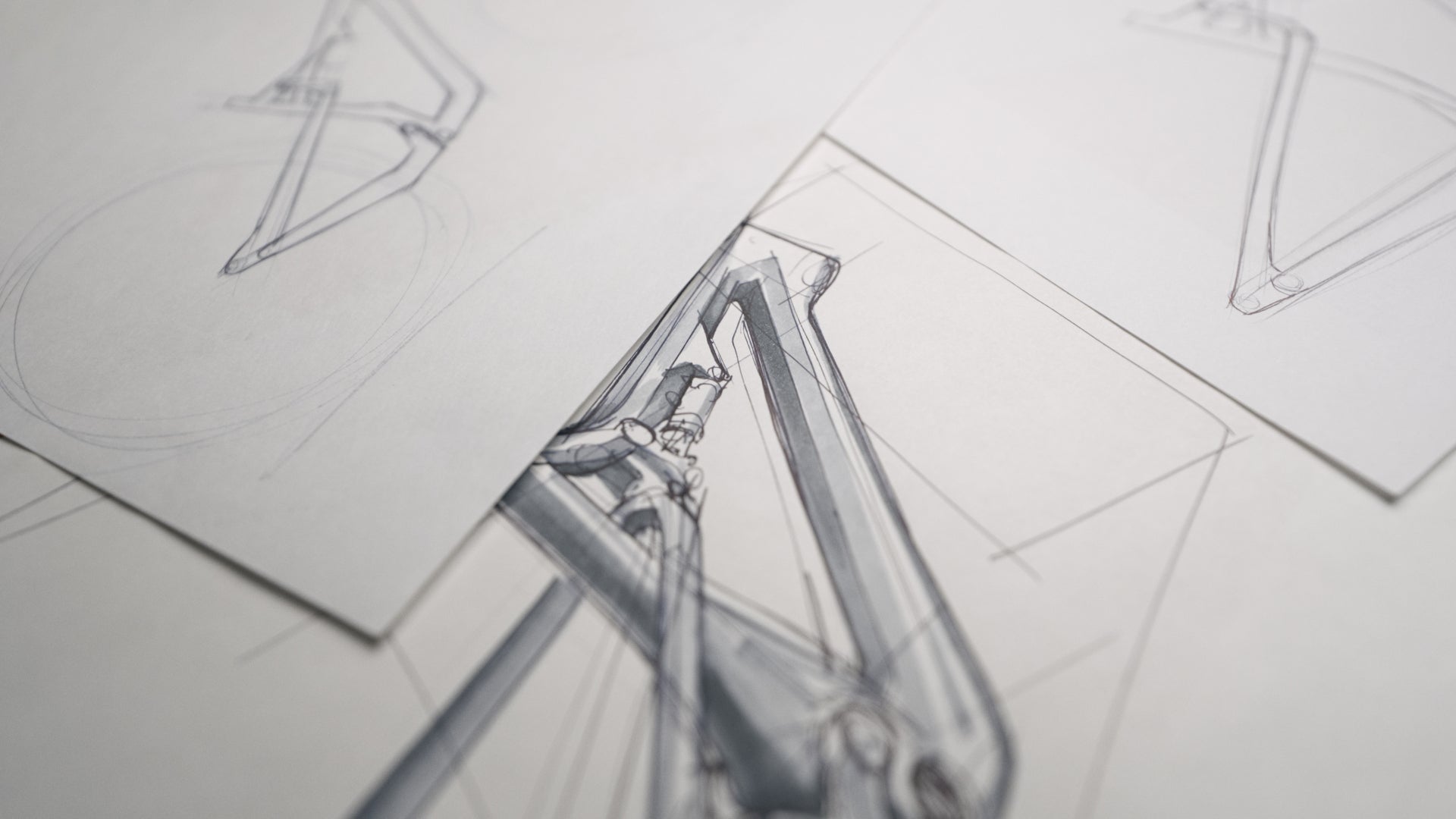

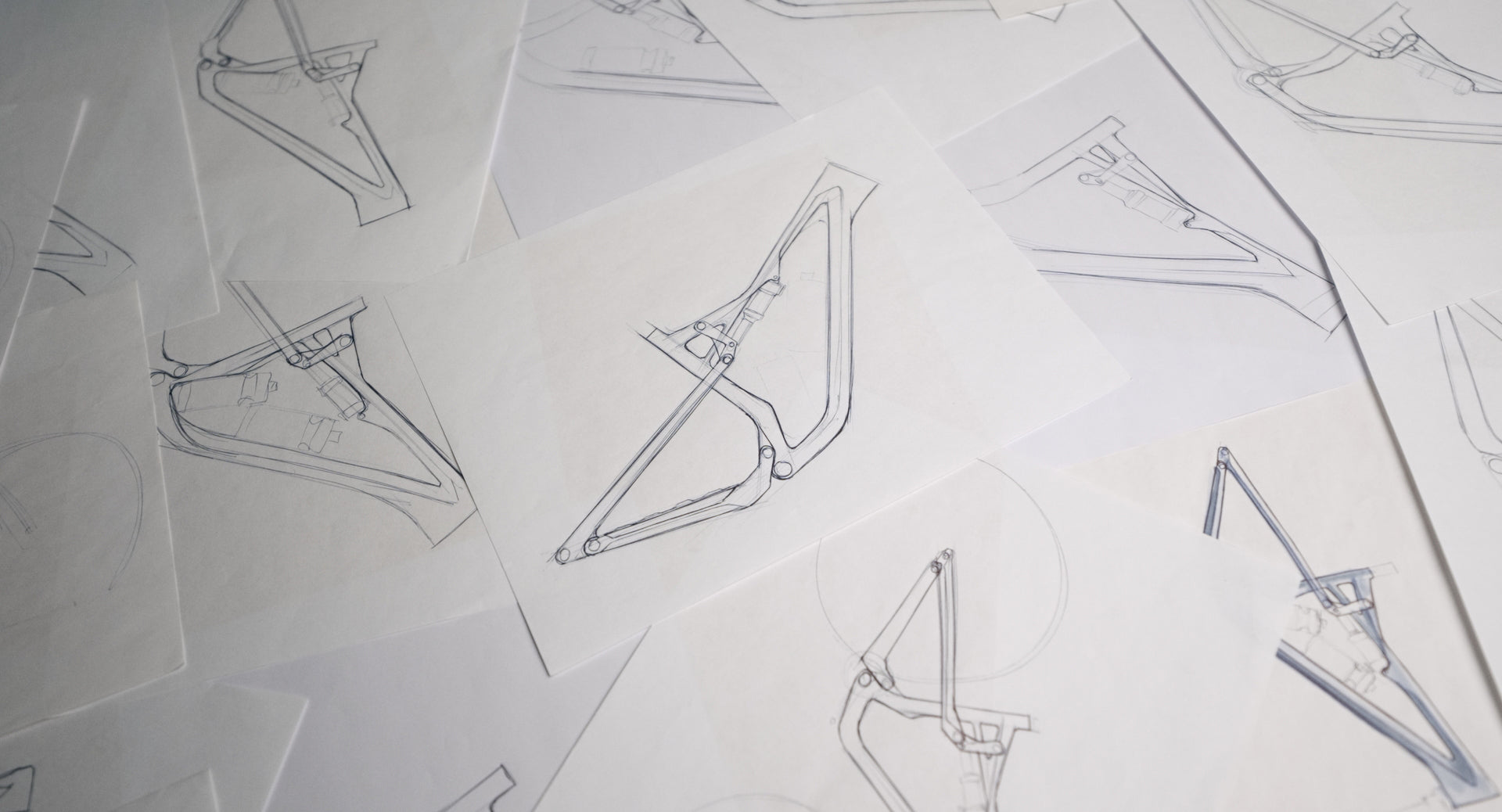

Design Process

Fezzari takes a forward-thinking approach to all its designs. Bikes are designed in-house in Lindon, UT and done with the utmost attention to detail.

Design to Reality.

The process of building a new bicycle is a unlike anything else. From initial conception to delivering the first bike to an ecstatic customer, we put in countless hours and resources to develop the best possible bikes across all major cycling disciplines. Passion, persistence, and constant refinement are our maxim as we hone our craft and deliver exceptional riding experiences to everyone who has the opportunity to ride a Fezzari. When one project is completed, we begin a new, synthesizing our acquired knowledge to develop the next generation of the bicycle evolution.

Stiffness and strength.

We use carbon fiber on frames, seat posts, forks, and other components. Carbon fiber is very light and can be made stiff or flexible. The term commonly used to describe stiffness is ''modulus''.

Less waste and lighter frames though better technology.

In traditional carbon layup processes, sheets of carbon are wrapped around an air bladder that has some type of object inside the bladder to keep the form, think of a paper mache project. Then after all the carbon is wrapped around the bladder, the object holding the shape is removed and the bladder and carbon fiber are placed in a mold. The bladder is inflated and baked. The problem in this process is that there is a lot of waste. The carbon wrapping has to be loose enough to pull the object out of the bladder before the curing process. This loose wrapping can cause overlapping carbon fiber that can weaken the frame or cause unnecessary weight, and creates air pocket voids causing potential frame failure.

Stiffness and strength.

We use carbon fiber on frames, seat posts, forks, and other components. Carbon fiber is very light and can be made stiff or flexible. The term commonly used to describe stiffness is ''modulus''.

Design to Reality.

The process of building a new bicycle is a unlike anything else. From initial conception to delivering the first bike to an ecstatic customer, we put in countless hours and resources to develop the best possible bikes across all major cycling disciplines. Passion, persistence, and constant refinement are our maxim as we hone our craft and deliver exceptional riding experiences to everyone who has the opportunity to ride a Fezzari. When one project is completed, we begin a new, synthesizing our acquired knowledge to develop the next generation of the bicycle evolution.

Stiffness and strength.

We use carbon fiber on frames, seat posts, forks, and other components. Carbon fiber is very light and can be made stiff or flexible. The term commonly used to describe stiffness is ''modulus''.

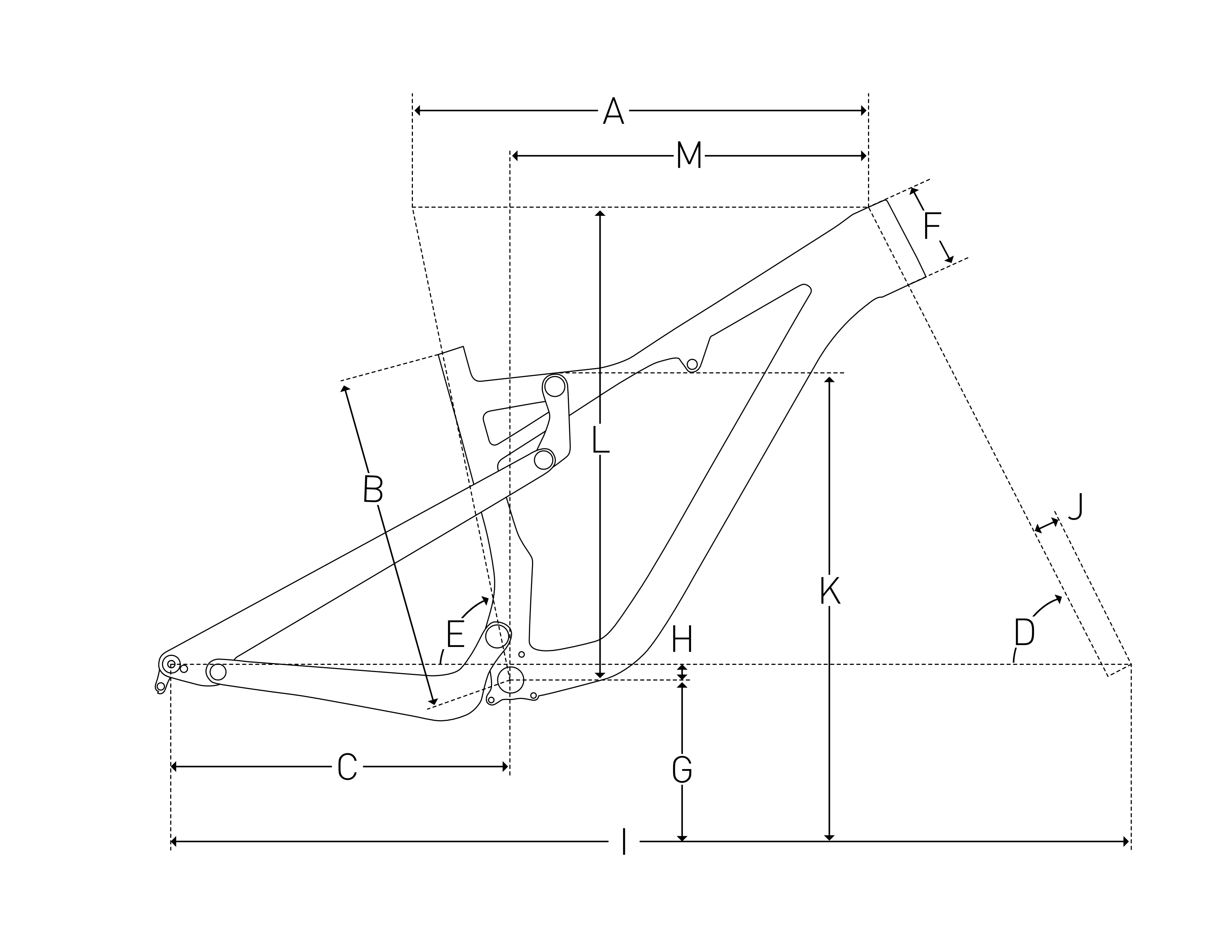

Geometry

Wheels

Units

| S | M | L | XL | |

|---|---|---|---|---|

| Top Tube | 560 | 593 | 613 | 637 |

| Seat Tube | 400.0 | 420.0 | 445 | 460.0 |

| Chainstay | 434 | 434 | 434 | 434 |

| Head Angle | 65° | 65° | 65° | 65° |

| Seat Angle (Effective)* | 77.5° | 77.5° | 77.5° | 77.5° |

| Head Tube | 95 | 95 | 115 | 130 |

| Bottom Bracket Height | 345 | 345 | 345 | 345 |

| Bottom Bracket Drop | 28.3 | 28.3 | 28.3 | 28.3 |

| Wheelbase | 1176.7 | 1209.7 | 1234 | 1260 |

| Fork Offset | 44.0 | 44.0 | 44.0 | 44.0 |

| Standover Height | 734 | 741 | 751 | 763 |

| Stack | 610 | 610 | 628 | 642 |

| Reach | 430 | 455 | 480 | 500 |

| S | M | L | XL | |

|---|---|---|---|---|

| Top Tube | 560 | 593 | 613 | 637 |

| Seat Tube | 400.0 | 420.0 | 445 | 460.0 |

| Chainstay | 433 | 433 | 433 | 433 |

| Head Angle | 65.4° | 65.4° | 65.4° | 65.4° |

| Seat Angle (Effective)* | 77.9° | 77.9° | 77.9° | 77.9° |

| Head Tube | 95 | 95 | 115 | 130 |

| Bottom Bracket Height | 343 | 343 | 343 | 343 |

| Bottom Bracket Drop | 22.8 | 22.8 | 22.8 | 22.8 |

| Wheelbase | 1175 | 1208 | 1233 | 1260 |

| Fork Offset | 44 | 44 | 44 | 44 |

| Standover Height | 734 | 741 | 751 | 763 |

| Stack | 603.5 | 603.5 | 621.8 | 635.5 |

| Reach | 435.6 | 467.4 | 483.3 | 504.8 |

Behind the Bike - Delano Peak

SUPPORT

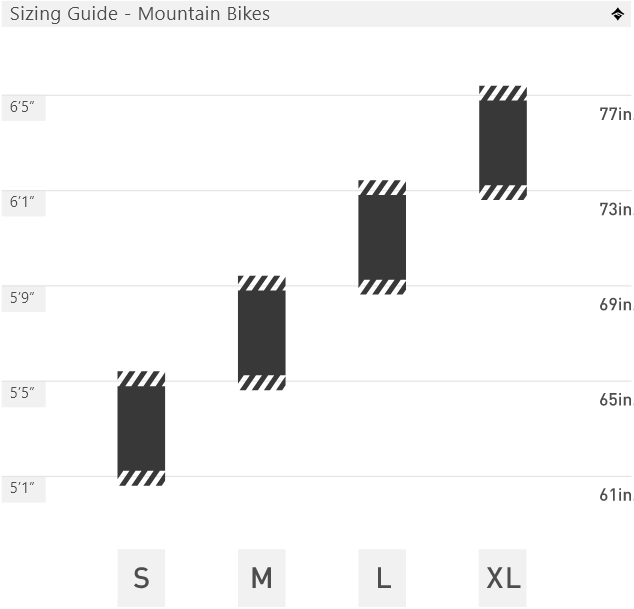

Your height will determine a general recommended frame size. Occasionally, based on other body measurements, you may feel more comfortable on a different size. We recommend completing the 23-point custom when completing your order.

Medium, Large and XL frames can accommodate two 21 oz. water bottles inside the front triangle; one on the down tube, and one on the seat tube. Small frames allow for the versatility of placing a water bottle on the down tube or seat tube mounts and using the other mount for tools. All sizes can have an optional third bottle mounted underside the downtube. Longer bolts need to be used to accommodate the bottle cage with the down tube guard installed

Every frame size has a 300mm insertion depth. This will fit almost every size dropper post. The exact dropper post length installed will depend on several factors including: rider inseam, crank arm length, length of crank arms, stack height of the dropper post seat clamp, stack height of the bushing collar of the dropper post, and seat height. As part of our 23-Point Custom Setup™, we ensure that each rider’s bike comes custom fit with the longest possible dropper post that will fit you so that you have the most comfortable and confident ride in every situation.

73mm English thread. Our philosophy is simple, if the bike is intended to be ridden in the dirt, it gets a threaded bottom bracket. Threaded bottom brackets are easier to service.

The Delano features the all new SRAM Universal Derailleur Hanger (UDH). We chose this derailleur hanger for simplicity, reliability, and performance. In the event of an impact to your rear derailleur, the derailleur hanger will bend away and help protect the frame and derailleur from irreparable damage. The UDH can be purchased directly from Fezzari.com.